Function and Composition of Starter

The function of the starter

The function of the starting system is to realize the smooth start of the engine. It consists of a starter, a starter relay, etc. The function of the starter motor is to convert the electrical energy of the battery into mechanical energy and transmit it to the flywheel of the engine to drive the crankshaft of the engine to rotate. The function of the starter relay is to control the work of the starter. On some models, the charging indicator relay and the starter relay are arranged into one body, which is called a combined relay and can also play the role of start-up protection.

To meet the requirements of starting the engine smoothly under low-temperature conditions, some loaders are equipped with a low-temperature auxiliary starting device (also called a start-up preheating device). Start performance.

Composition of starter

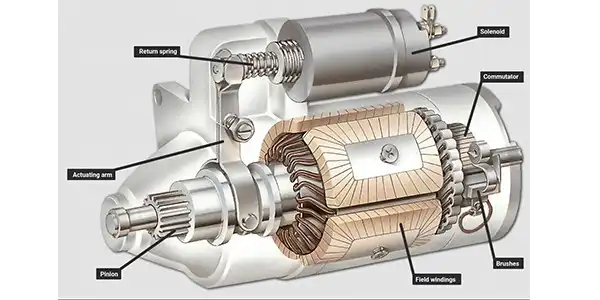

The starter consists of a series-excited DC motor, a transmission device, and an operation control device.

Electric motor

The function of an electric motor is to generate torque. The excitation mode of the motor for starting is series excitation. Due to the large working current of the starter, the large torque, and the short working time, it generally does not exceed 5~10s. The motor consists of the magnetic field, armature, and brush assemblies.

1) Magnetic field: It consists of the magnetic field winding, the magnetic pole (iron core), and the outer casing of the motor. The four magnetic poles of the excitation coil are wound, and the N and S poles are installed on the shell alternately. The field winding is made of flat and thick copper wire, and each winding has a small number of turns. Two of the four windings are connected in series and then two groups are connected in parallel, one end of which is connected to the insulating post of the casing, and the other end is connected to the brush.

2) Armature: It consists of armature winding, iron core, armature shaft, and commutator. The iron core is laminated by silicon steel sheets and fixed on the shaft. The armature winding is embedded in the slot of the iron core, and the silicon steel sheets are insulated with insulating paint or oxide. The winding is made of thick rectangular sections of bare copper wire. To prevent the bare copper wire from short-circuiting, the conductor and the iron core, the conductor, and the conductor are separated by insulating paper with good insulation performance. To prevent the conductor from being thrown out under the action of centrifugal force, the iron cores on both sides of the slot are squeezed tightly by rolling.

Each end of the armature winding is welded on the commutator, and the current of the battery is introduced into the armature winding through the contact between the commutator and the brush. The commutator is made by laminating copper sheets and mica sheets.

A transmission keyway is made on the armature shaft to cooperate with the one-way clutch. The armature shaft is generally supported by the front and rear end caps and the middle support plate at three points, using graphite bronze sliding bearings. The tail end of the shaft is thin, and a thrust washer is installed between the shoulder and the rear end cover.

Brush: installed in the brush holder, the brush is pressed on the commutator by the spring. To reduce the current density of the brushes, the number of brushes is generally equal to the number of magnetic poles, that is, four brushes, arranged in positive and negative phases. The brush material is pressed from 80%~90% copper and graphite. The brush holder is fixed on the brush end cover of the motor.

Our website also provides engine thermostat 3928639, you can buy a variety of spare parts for excavators, and aerial platforms on our website.

Track Your Order

Track Your Order