How Does A Fuel System Work?

Fuel is vital to the engine and is an important element in the combustion process so it can convert into energy to propel your vehicle. It mixes with air, ignites, and eventually turns into the exhaust. The function of the automobile fuel system is to store and supply fuel to the engine. The engine intake system is where fuel mixes with air, atomize and vaporizes. It can then be compressed in the engine cylinder and ignited to generate energy or power. And how do the various components cooperate to complete this process?

1. Electric gasoline pump: The gasoline pump of an EFI engine is driven by the motor, so it is also called an electric gasoline pump, which is an integrated body of motor and oil pump, installed in the fuel tank, there are two types of common electric gasoline pumps, that is, rolling Column type electric gasoline pump and vane type electric gasoline pump.

2. Fuel distribution pipe: fuel distribution pipe, also known as a distribution pipe or common rail, has the function to deliver gasoline to the spare cylinder injector evenly and at equal pressure. Due to the large volume, it has the function of storing oil and pressure and slowing down the oil pressure pulsation.

3. Fuel injector: The function of the injector is to inject a certain amount of gasoline into the intake port or intake pipe in a timely manner according to the instructions of the electronic control unit, and mix it with the air in it to form a combustible mixture. The power on and off of the fuel injector is controlled by the electronic control unit. The electronic control unit outputs control current to the fuel injector in the form of electrical pulses. When the electric pulse rises from zero, the fuel injector is turned on due to electricity. When the electric pulse falls back to zero, the fuel injector shuts down again due to power failure.

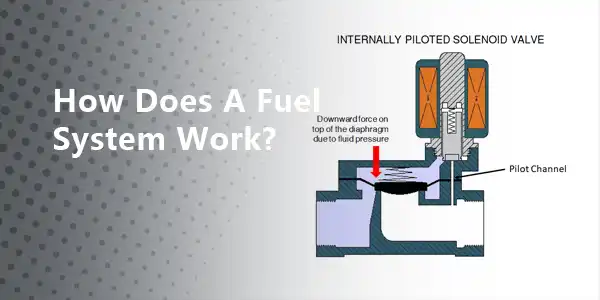

4. Oil pressure regulator: The function of the oil pressure regulator is to keep the difference between the pressure of the fuel supply system and the pressure of the intake pipe, that is, the fuel injection pressure, constant. Because the fuel injection star of the fuel injector is not only dependent on the fuel injection duration but also related to the fuel injection pressure. In the same fuel injection duration, the higher the fuel injection pressure, the more fuel injection. The fuel stop solenoid also plays an important role in fuel quantity regulation. Therefore, only by keeping the fuel injection pressure constant, can the fuel injection volume under various loads only depend on the fuel injection duration or the electric pulse width, so as to realize the precise control of the fuel injection volume by the electronic control unit.

5. Oil pulsation buffer: When the gasoline pump oil, the fuel injector sprays, and the oil return plane valve of the oil pressure regulator opens and closes, it will cause pulsation and pulsation noise of the oil pressure in the fuel pipeline. Fuel pressure pulsation is too large to make the oil pressure regulator work abnormally. The role of the oil pressure pulsation buffer is to reduce the pulsation and pulsation noise of the oil pressure in the fuel line, and to maintain a certain pressure in the oil line after the engine stops, so as to facilitate the restart of the engine.

6. Cold start nozzle and hot time switch The function of the cold start nozzle is to inject a certain amount of additional gasoline into the intake pipe to enrich the mixture when the engine starts at a low temperature. The cold super-motion nozzle is also a solenoid valve, so it is also called a cold start valve. The opening and holding time of the cold start nozzle depends on the temperature of the engine and is controlled by the thermal time switch. The cold start nozzle is installed on the intake pipe, and the hot time switch is installed on the body and is in contact with the coolant.

Track Your Order

Track Your Order