Maintenance of Hydraulic System of Excavator

Excavators are some of the most essential equipment in the construction industry. They are used for a variety of tasks, such as excavation, grading, and demolition. However, like all machinery, they require regular maintenance to perform optimally. The hydraulic system is particularly important in an excavator, and proper maintenance of this system is crucial for the machine's efficient and effective operation.

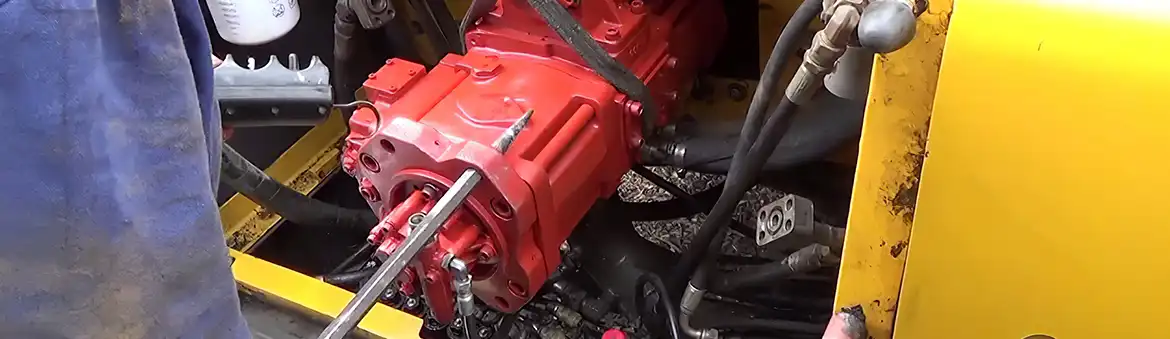

The hydraulic system of an excavator is made up of several components, including a hydraulic oil tank, a main pump, a multi-way valve, various pipelines and cylinders that perform various actions, motors, and other precision machined parts. The hydraulic system is like the blood circulation system of the human body, and it is spread throughout the entire excavator. The system must be maintained correctly to prevent failure, which can cause the machine to stop and lead to losses.

There are three key points to keep the hydraulic system clean. The first is to keep the hydraulic oil clean. The oil should be stored in a clean place, and care should be taken when changing or refueling. Only a clean funnel fitted with a fine mesh strainer should be used to pour oil from the container into the tank. Additionally, the oil used must be the type recommended by the manufacturer.

The second point is to regularly replace hydraulic oil and filters. Good hydraulic oil contains a variety of additives that prevent the oil from deteriorating. However, these additives lose their effectiveness over time, and the oil should be changed regularly to ensure that they are still working. Filters can only absorb a limited number of dirt particles and other impurities from the oil. When replacing the hydraulic oil filter, it is important to check whether there are metal particles or debris at the bottom of the filter. Copper or iron filings indicate damage to the hydraulic pump, hydraulic motor, or valve, while rubber means that the hydraulic cylinder seal is damaged.

The third point is to regularly discharge oil tank dirt. Regularly releasing water and sediment in the oil tank is crucial for removing impurities in the oil. However, it is also important to regularly replace the hydraulic oil in the entire hydraulic system. This is the only reliable way to completely remove system impurities, oxidized hydraulic fluid, and other harmful impurities. After draining the old oil, the hydraulic system should be filled with clean hydraulic oil recommended by the manufacturer.

When maintaining the hydraulic system, it is important to keep the work area clean. When refilling or refueling the reservoir with hydraulic fluid, the area around the filter box cover must be clean. Only clean funnels or containers should be used, and dirt should never be brought into the system. When maintaining the hydraulic system, only clean plastic plugs should be used to seal the ends of the lines. When maintaining hydraulic components, the workbench must be absolutely clean. It is important to check the condition of the tools used, as they should also be very clean.

Regular maintenance of the hydraulic system in an excavator is crucial for optimal machine performance. The hydraulic system is essential for the excavator's operation, and it must be maintained correctly to prevent failure, which can lead to machine downtime and losses. Proper maintenance of the hydraulic system includes keeping the hydraulic oil clean, regularly replacing hydraulic oil and filters, and regularly discharging oil tank dirt. Additionally, it is important to keep the work area clean when maintaining the hydraulic system and to check the condition of the tools used. By following these guidelines, excavator owners can ensure that their machines perform optimally and minimize downtime and losses.

Looking for hydraulic system parts for your heavy equipment? Look no further than MyMROmarts! We are your one-stop shop for aftermarket, OEM, and genuine parts, with over 50,000 parts in stock and fast delivery within 2-7 days. Plus, we offer a 30-day return/exchange policy and 100% secure payment options. Shop now and get the parts you need for your equipment!

Track Your Order

Track Your Order