What Are The Types of Oil Pumps?

The functions of oil pump

The oil pump sends the oil in the oil pan to the oil filter and lubricates oil passages after pressurization, so as to lubricate the main moving parts of the engine and filter the oil. When the engine is working, the oil pump works continuously, so that the oil circulates continuously in the lubricating oil circuit.

Since the speed of the oil pump is directly proportional to the engine speed, the oil supply capacity of the oil pump is the worst at low speeds. There are two types of oil pumps used in automobile engines: gear type and rotor type. The working principle of these two kinds of oil pumps is the same, and they both use the change of volume to change the low-pressure oil into high-pressure oil, so they are also called positive displacement oil pumps. It is characterized by a simple structure, reliable operation, and convenient manufacture and repair.

The oil pump function is to transport or pressurizes a liquid. It transfers the mechanical energy of the prime mover or other external energy to the liquid to increase the energy of the liquid. The pump is mainly used to transport liquids such as water, oil, acid and alkali liquid, emulsion, and liquid metal, and can also transport liquid, gas mixture, and liquid containing suspended solids.

2 types of oil pump

- Meshing gear oil pump

The gear oil pump is composed of a driving shaft, a driving gear, a driven shaft, a driven gear, and a housing. Two gears with the same number of teeth mesh with each other and are installed in the housing. The radial and end clearances between the gears and the housing are very small. The driving shaft is keyed to the driving gear, and the driven gear is vacantly sleeved on the driven shaft.

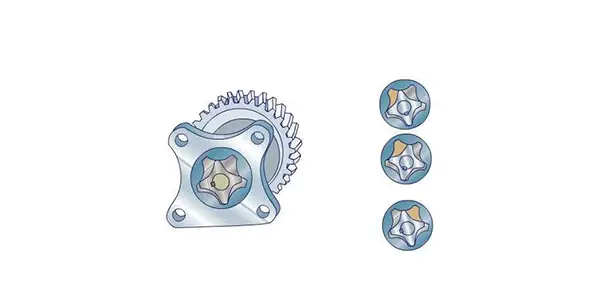

- Rotor oil pump

The rotor-type oil pump uses the inner and outer rotors to pressurize lubricating oil, also known as the trochoidal gear pump. The rotor-type oil pump is mainly composed of inner and outer rotors, the oil pump body and oil pump cover, and other parts. Both the active inner rotor and the driven outer rotor are installed in the oil pump casing. The inner rotor has four convex teeth, and the outer rotor has five concave teeth. The inner rotor is fixed on the driving shaft, and the outer rotor can be freely Rotated, there is a certain eccentricity between the two.

The oil pump is characterized by a simple structure, small size, lightweight, and large oil delivery capacity. The cycloidal rotor pump adopts the meshing structure of the inner and outer rotors. It has a small number of teeth and a compact structure size. It can form a sealed cavity without other isolation elements and has a small number of parts.

Track Your Order

Track Your Order