What is the Function of the Piston Ring?

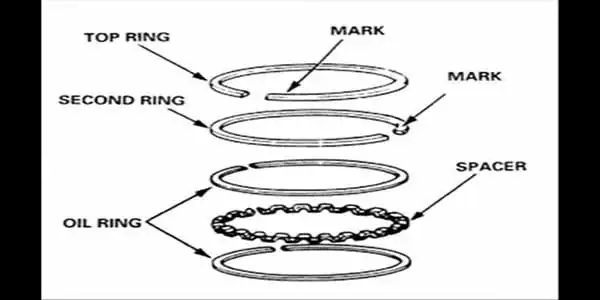

There are two types of piston rings: one is the compression ring and the other is the oil ring. The piston ring is a metal elastic ring with outward expansion, the compression ring is used to seal the combustible gas in the fuel chamber, and the oil ring is used to scrape the excess oil on the cylinder. Rotating the piston ring back and forth depends on the pressure ratio between the gas and the liquid.

1. The Function of the Piston Rings

(1)Sealing, Heat Transfer

Ensure the seal between the piston and the cylinder wall, prevent the combustible mixture and high-temperature gas in the cylinder from leaking into the crankcase, and transfer the heat received by the top of the piston to the cylinder wall to avoid overheating of the piston. The main function of the oil ring is to scrape off the excess oil splashed on the cylinder wall and coat a uniform oil film on the cylinder wall. When the piston ring is working, it is affected by the high temperature and high-pressure gas in the cylinder, and it slides at high speed in the cylinder under the condition of poor lubrication. Due to the shape error of the cylinder wall surface, the piston ring slides up and down and radially moves in the ring groove at the same time. This not only aggravates the wear of the ring and the ring groove but also makes the piston ring easily broken due to the alternating bending stress.

(2)Piston Ring Material and Surface Treatment

According to the function and working conditions of the piston ring, the material for making the piston ring should have good wear resistance, thermal conductivity, heat resistance, impact toughness, elasticity, and sufficient mechanical strength. At present, the widely used piston ring materials are high-quality gray cast iron, ductile iron, alloy cast iron, and steel belts. The outer surface of the piston ring is usually chromed or sprayed with molybdenum. The porous chromium layer has high hardness and can store a small amount of oil, which can improve lubrication and reduce wear. Molybdenum has a high melting point and is also porous, so spraying molybdenum can also improve the wear resistance of piston rings.

2. The Four Functions of the Piston Ring

(1)Oil Control Function Of A Piston Ring

The oil splashed or sprayed on the cylinder wall is evenly distributed on the cylinder wall, and the excess oil is scraped off, and the scraped oil is returned to the crankcase through the gap between the piston and the cylinder liner and the drain hole of the piston oil groove, where the oil ring Control 70% to 90% of the oil, and the gas ring controls 10% to 20% of the oil.

(2) Support Function Of Piston Ring

When the piston and the piston ring reciprocate synchronously, the piston exerts a large positive pressure on the piston ring, that is, the reciprocating inertial force. When the crank connecting rod produces side pressure on the piston and wants to deflect the piston, the piston ring exerts a frictional reaction force on the piston due to the action of the positive pressure, thereby supporting the piston.

(3) Thermal Conductivity Of Piston Rings

70% of the heat on the piston is directed to the cylinder wall through the end face of the piston ring, and the middle channel and the second channel play a leading role in heat conduction, thus ensuring the thermal balance of the piston.

(4) Sealing Function Of A Piston Ring

In the compression and power strokes, the piston ring seals the gas from top to bottom. The ring seals 80% to 90% of the gas, the second ring seals 10% to 20% of the gas, and the third ring is oil. Ring, which seals about 5% of the gas.

In conclusion, the function of a piston ring plays an important role in the operation of internal combustion engines. The functions of piston rings include sealing combustible gases, transferring heat, controlling oil distribution, and providing critical support for the piston. Piston ring design and material composition are important considerations.

Track Your Order

Track Your Order