How Does A Fuel Shut Off Solenoid Work?

In modern construction machinery, the fuel shut-off solenoid valve is a key control element. It plays an important role in the fuel supply system of the engine. In this article, MyMROmarts will explore how a fuel shut off solenoid work and how to troubleshoot the fuel shutoff solenoid if it fails to work.

What Is A Fuel Solenoid Valve?

The fuel shut off valve solenoid is an engine part that uses electromagnetic force to control the flow of fuel. By energizing or de-energizing the solenoid coil, the valve can be quickly opened or closed. The fuel solenoid valve is mainly used to cut off the fuel supply in an emergency to ensure the safe operation of the engine.

What Does A Fuel Shut Off Solenoid Do?

The main function of the fuel shut off valve solenoid is to control and manage the flow of fuel. In an emergency, the fuel solenoid valve can quickly cut off the fuel supply to prevent fire or other safety risk events. In addition, the fuel solenoid ensures timely opening and closing of the fuel supply when heavy equipment is started and stopped. The existence of the fuel shut off valve solenoid ensures the normal operation of the fuel system.

How Does A Fuel Shut Off Solenoid Work?

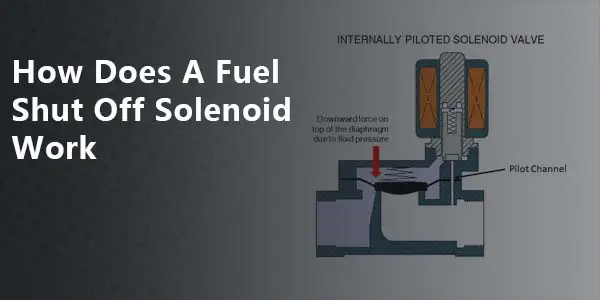

A diesel fuel shut off solenoid is an electromagnetically operated valve used to remotely shut off the fuel supply to an engine. The fuel shut off solenoid typically consist of a valve body and a complete solenoid assembly attached to a valve stem. When the fuel shut off solenoid is energized, the movement of its plunger retracts the spring-loaded poppet from its seat, allowing fuel to pass through the valve. When the diesel fuel shut off solenoid is deactivated, the valve spring pulls the poppet valve back onto its seat, effectively shutting off fuel flow.

The diesel fuel shut off solenoid can be activated manually or as part of an automatic engine management system. The diesel shut off solenoid is among the most important commonly used remote fluid flow devices and are used in a wide variety of applications. A fuel shut off solenoid valve is a device used to remotely or, in some cases, automatically shut off the fuel supply to an engine or burner. These valves are usually integral units consisting of two separate devices. The first is the actual fuel shutoff device which in most cases is a very traditional brass poppet type valve. The valve operating rod is connected to a plunger that is usually mounted on a solenoid at the top of the valve body. When a suitable current is passed through the solenoid, a strong magnetic field is generated around it. This magnetic field attracts the solenoid plunger, quickly pulling it toward the coil. Connected to the valve stem, the moving solenoid plunger will lift the valve seat, allowing fuel to pass through the valve. When the diesel fuel shut off solenoid is de-energized, the valve spring pulls the poppet back to its fixed position, closing the valve and resetting the diesel solenoid valve, ready for the next duty cycle. Power to activate the diesel fuel shut off solenoid can be manual or controlled by an automatic system.

These valves typically open when the system start-up procedure is initiated and close if a hazardous condition is detected. This will immediately cut off the flow of fuel to the burner or engine, effectively preventing the escalation of the hazard.

How To Troubleshoot The Fuel Shut off Solenoid If It Fails To Work?

The fuel cut-off solenoid valve is one of the important components in the diesel engine fuel system components. Troubleshooting a fuel shutoff solenoid requires careful inspection and stepping through possible problems. Here are some common troubleshooting steps:

a. Make sure the power connection to the diesel fuel shut off solenoid is secure and that the wires are not damaged or broken. Use a multimeter to check whether the power supply is normal to ensure that the diesel fuel shut off solenoid can receive power normally.

b. Verify that the control signal reaches the fuel shut off solenoid. Use an oscilloscope or a multipurpose voltmeter to check whether the waveform and voltage of the control signal are normal.

c. The core components of the fuel shut off solenoid are the electromagnet and the spool. Check that the electromagnet is working properly and make sure it generates enough magnetic field when energized. At the same time, check whether the spool is unblocked and free from jamming or wear.

d. Occasionally, the diesel fuel shut off solenoid may malfunction due to oil, dirt, or foreign objects becoming clogged. Regular cleaning and maintenance of the fuel shut off solenoid, especially the valve core and valve body, can effectively prevent failures.

e. Springs and seals are critical components to keep the spool sealed and return to position. Check the springs for damage or deformation and make sure the seals are not leaking.

f. Check whether the fuel oil circuit related to the fuel shut off solenoid valve is normal, and make sure there is no blockage or leakage.

g. If a component is found to be faulty after troubleshooting, replace it in time. Common faulty components include damaged solenoids, spools, springs or seals, etc.

h. After eliminating all possible problems, carry out testing and debugging to ensure that the function of the diesel fuel shut off solenoid returns to normal. Take care to stay safe while testing to prevent injury or other damage due to mishandling.

In conclusion, the diesel fuel shut off solenoid valve is a key component in modern construction machinery and engine systems. Its operation is controlled by electromagnetic principles, allowing remote or automatic control of fuel flow to the engine. The diesel fuel shut off solenoid opens the fuel valve when energized and closes it when deactivated, effectively managing the fuel supply. However, like any mechanical component, these solenoids can experience problems. Resolving the failing component and performing thorough testing and debugging are critical steps in keeping your diesel fuel shut-off solenoid valve functioning properly. Understanding how diesel engine stop solenoid works is very important to ensure the efficient and safe operation of mechanical equipment.

Track Your Order

Track Your Order