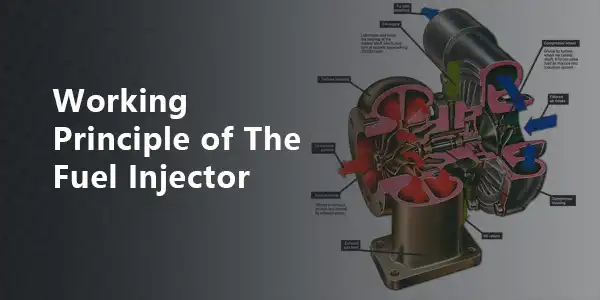

Working Principle of The Fuel Injector

Brief Introduction of the Fuel Injector

The fuel injector is the part responsible for controlling the injection of fuel into the internal combustion chamber of the engine. The fuel injector is a precision device with very high machining accuracy, which requires a large dynamic flow range, strong anti-clogging and anti-pollution capabilities, and good atomization performance. The fuel injector receives the fuel injection pulse signal sent by the ECU (electronic control unit) to precisely control the fuel injection quantity.

Working Principle of the Fuel Injector

The Closed fuel Injector Working Principle

There are two types of injectors: open and closed. The open fuel injector working principle is simple and has a simple structure, but poor atomization, so it is rarely used. Closed injectors like fuel injector 400903-00074d for Doosan d24, are widely used in various diesel engines. Diesel engines inhale pure air during the intake stroke. When the compression stroke is near the end, the diesel oil will increase the oil pressure to above 100MPa through the fuel injection pump, and then spray into the cylinder through the fuel injector, and mix with the compressed high-temperature air in a short time to form a combustible mixture.

Due to the high compression ratio of the diesel engine (generally 16-22), the air pressure in the cylinder can reach 3.5-4.5MPa at the end of the compression, and the temperature can reach as high as 750-1000K (while the gas mixture pressure of the gasoline engine at this time will be 0.6-1.2MPa , the temperature reaches 600-700K), which greatly exceeds the self-ignition temperature of diesel. Therefore, after diesel is injected into the cylinder, it will ignite and burn by itself immediately after mixing with air in a short time. The air pressure in the cylinder rises rapidly to 6-9MPa, and the temperature also rises to 2000-2500K. Pushed by the high-pressure gas, the piston moves downward and drives the crankshaft to rotate to do work, and the exhaust gas is also discharged into the atmosphere through the exhaust pipe.

The Common Rail Injection Oil supply System

The common rail injection oil supply system consists of a high-pressure fuel pump, a public fuel supply pipe, a fuel injector, an ECU and some pipeline pressure sensors. Each fuel injector in the system communicates with the public fuel supply through its own high-pressure fuel pipe. The common oil supply pipe acts as a hydraulic pressure accumulator for the injector. When working, the high-pressure oil pump delivers the fuel to the public fuel supply pipe at high pressure, and the high-pressure fuel pump, pressure sensor and ECU form a closed-loop operation to achieve precise control of the oil pressure in the public fuel supply pipe, completely changed the phenomenon that the oil supply pressure changes with the engine speed. Its main features are the following three aspects:

1. The fuel injection timing is completely separated from the fuel metering, and the fuel injection pressure and fuel injection process are controlled by the ECU in a timely manner.

2. The fuel injection pressure, fuel injection starting point and duration of each cylinder can be adjusted according to the working conditions of the engine, so as to pursue the best control point of fuel injection.

3. It can realize high fuel injection pressure and pre-injection of diesel.

Track Your Order

Track Your Order